Cool Roofs, Hot Cities: Insights from Field Evidence and Real-World Application

By akanksha agrawal, akhil singhal, tarun garg – rmi india foundation; aun abdullah – lodha

June 25, 2025Introduction

Urban Heat Islands (UHI) occur when cities become significantly hotter than their rural surroundings due to heat-retaining surfaces and human activities. In India’s rapidly growing cities, typical urban-rural temperature differences range from 1–5 °C and can reach up to 8 °C in extreme cases.[1] This intensifying heat not only worsens outdoor thermal discomfort but also drives up energy use for cooling and amplifies heat-related health risks.

In India’s warm and humid coastal cities like Mumbai and Chennai, high ambient temperatures combined with sustained humidity levels (often 60–80%) significantly reduce nighttime cooling and further exacerbate heat stress for residents.[2] Densely built, poorly ventilated districts experience the worst effects, especially during heatwaves, which hit cities harder due to the compounding UHI effect.

Cool Roofs have emerged as a practical, high-impact solution to help combat this. As defined by the Cool Roof Rating Council, “A cool roof is one that strongly reflects sunlight (solar energy) and also cools itself by efficiently emitting any heat that was absorbed. The two basic characteristics that determine the 'coolness' of a roof are solar reflectance and thermal emittance. Both properties are measured on a scale from 0 to 1, where 1 is 100% reflective or emissive.” Cool roofs lower the roof surface temperature by reflecting incoming solar radiation and releasing absorbed heat, which in turn reduces indoor temperatures, cooling energy demand, and the total heat released into the urban environment. The widespread adoption of cool roofs can make neighbourhoods cooler and more comfortable, mitigating the UHI effect at both the building and city scale.[3]

A recent pilot was conducted in the housing development area of Chennai, built using precast technology, for low-income residents with no access to air conditioning. The results demonstrated that simply applying a reflective cool coating on concrete rooftops reduced roof surface temperatures by 9–12 °C (from ~42 °C down to ~30 °C) and brought down indoor room temperatures by 0.5–2 °C, resulting in improved occupant comfort. These results underscore why cool roofs matter – they offer an affordable, scalable means to relieve urban heat stress and also protect vulnerable communities from extreme heat.

Performance Benefits and Economic Viability of Cool Roofs

Cool roofs deliver a range of performance benefits – from mitigating Urban Heat Island (UHI) effects across neighbourhoods to improving indoor thermal comfort and reducing cooling loads inside buildings – all at relatively low cost.

At the city scale, field pilots and simulations have shown that large-scale cool roof adoption can lower ambient air temperatures by 1–2°C during peak summer months.[4] In Ahmedabad’s pilot programs, densely populated neighbourhoods with widespread cool roof adoption recorded localised temperature reductions of up to 2°C, improving outdoor comfort and reducing heat stress during heatwave periods.

Similarly, studies in Hyderabad demonstrated that cool roofs could reduce A/C electricity consumption by 10–19% for uninsulated concrete roofs, corresponding to 13–14 kWh/m² of annual energy savings. [5]This translates into a reduction of about 11–12 kg of CO₂ emissions per square meter annually, considering India’s average grid emission factor.

From an economic perspective, cool roofs are one of the most cost-effective heat mitigation strategies available today. Capital costs (CAPEX) for cool roofs in India are moderate across different technologies:

- Simple white lime finishes or lime plasters, commonly used in traditional construction, can offer basic reflectivity benefits starting from as low as ₹5–10 per square foot (₹55–110/m²).

- White elastomeric cool coatings are available in the range of ₹20–50 per square foot (₹215–540/m²), depending on product quality and warranty coverage.

- High-albedo ceramic or porcelain tiles cost between ₹50 and ₹ 100 per square foot, offering a longer lifespan with minimal maintenance, provided they are installed as per standard procedures. This underscores the need for an application manual including operations and maintenance guidelines.

Operating and maintenance costs (OPEX) for cool roofs are low. Most coatings require only periodic cleaning (e.g., gentle washing every 6–12 weeks) to maintain surface reflectivity. However, it is important to ensure that products meet the aged Solar Reflectance Index (SRI) criteria to guarantee sustained thermal performance over time. Without appropriate material selection, coatings can lose effectiveness due to UV degradation, dust accumulation, and weathering. Recoating may be needed every 5–7 years for standard coatings, although premium products can retain high reflectivity for 10+ years. Table 1 summarises different Cool Roof solutions along with cost, key benefits, challenges and trade-offs.

| Solution Type(with Approx. SRI) | Key Benefits | Challenges | Cost (₹/m²) | Trade-offs | Case studies |

| Lime-based Whitewash(SR- 0.75-0.85, TE- 0.75-0.90) | Very low-cost; lowers indoor temp. by 2-3°C; improves comfort in non-AC homes; easy local application | Very short lifespan (~1 year); washes off in rain; needs annual recoating; informal application, adoption can be low unless subsidized or community-driven. | ₹5 – ₹25 | Ultra-low-cost vs. high maintenance; temporary solution best for short-term or emergency relief | https://www.preventionweb.net/news/india-keeping-it-cool-models-city-cool-roof-programs |

| Reflective Paint Coating- White elastomeric/acrylic-based (SRI- 80-120) | Reduces indoor temps by 2–5°C; easy to apply; can double as waterproofing; moderate cost | Requires recoating every 3–5 years; reflectance degrades with dust; performance drops without maintenance | ₹300 – ₹800 | Moderate cost and performance; low hassle but needs periodic upkeep to retain efficiency | https://shaktifoundation.in/wp-content/uploads/2017/06/cool-roofs-manual.pdf |

| Cool Roof Tiles including reflective clay tiles, ceramic shingles, china mosaic (SRI-70-100) | Reduce surface temperatures by 12-15℃. Long-term durability; no reapplication; improves thermal mass and waterproofing | High upfront cost; adds roof load; needs skilled installation; less suitable for sloped/weak roofs | ₹1,000 – ₹2,000 | High upfront vs no maintenance; long-term gains; not for weak structures or informal homes | Cool tiles were installed on the rooftop surface of a low-rise Villa at Palava city, Mumbai, with surface temperature reduction- 12-18°C |

| PDRC Coating (SR>0.9, TE>0.9) | Superior passive cooling; radiates heat to the sky; can cool below ambient; significant energy savings | Very high cost; R&D stage; performance in Indian conditions still under validation; limited availability | ₹1,700 – ₹2,000 | Max cooling but max cost; best for demo or premium users; unknown long-term durability | A pilot done by Ganzkuhl in a Hyderabad commercial building with a concrete rooftop showed 22-degree reduction with PDRC |

| Membrane-based Cool Roof -High-Density Polyethylene (HDPE), Thermoplastic Polyolefin (TPO) /Polyvinyl Chloride (PVC)membranes (SRI- 90-108) | Quick to install; improves comfort by ~2°C; protects the roof from rain; reusable and low-skill deployment | Short-to-medium lifespan; can tear or blow away; not permanently fixed; needs seasonal handling | ₹130 – ₹150 | Easy and fast vs fragile and temporary; cost-effective for low-income but needs replacement | https://www.preventionweb.net/news/india-keeping-it-cool-models-city-cool-roof-programs |

Table 1: Cool roof Solutions: key benefits, challenges and trade-offs

When evaluating heat mitigation strategies, cool roofs consistently emerge as one of the most scalable, affordable, and impactful options, validated by successful implementations globally and increasingly across India.

Cool Roofs in India- Supporting Policies governing the adoption

Policy Landscape : At the national level, various policy initiatives have been taken to support the uptake of cool roofs in the country. National building codes now recognise cool roofs as a key component of energy-efficient design. Table 2 provides details of National codes and rating systems that recommend a cool roof.

| Standard / Region | Type of Building | Solar Reflectance (SR) | Thermal Emittance (TE) | Solar Reflectance Index (SRI) | Mandatory / Optional | Ambiguities | Enabling Conditions |

| Eco Niwas Samhita (ENS) | Residential (Roofs <20° slope) | SR ≥ 0.60 | TE ≥ 0.90 | Not specified | Mandatory for prescriptive compliance | No clear SRI value or product testing standards; regional climatic factors not explicitly considered | Aligned with PMAY-U; provides incentive for energy efficiency in residential housing |

| ECBC (2017) | Commercial (Low-slope roofs) | SR ≥ 0.70 | TE ≥ 0.75 | SRI ≥ 78 | Mandatory for ECBC buildings | No mention of aged reflectance or long-term durability under Indian climate conditions | Forms basis for State ECBC notifications; linked to green building mandates |

| IGBC Rating | Commercial & Residential | SR ≥ 0.65 (suggested) | TE ≥ 0.75 (suggested) | Not specified | Optional (credit-based) | Suggested values-not binding, lacks contextual adaptation for Indian heat stress patterns | Awards point under Green Building criteria encourages integration into the design approach |

| GRIHA Rating | Commercial & Residential | SR ≥ 0.65 | TE ≥ 0.75 | Not specified | Optional under-point system | No minimum area defined for roof coverage; lack of guidance on product verification | Credits for sustainable roof materials and passive cooling measures |

Table 2 : Policies in India governing Cool Roofs adoption

Key Policy Insights Driving Cool Roof Adoption in India

- PMAY-U creates an entry point for cool roofs by encouraging energy-efficient, climate-resilient housing. Its alignment with Eco Niwas Samhita (ENS) enables the integration of passive cooling solutions like reflective surfaces in affordable homes.

Telangana leads the way with India’s first dedicated Cool Roof Policy (2023–2028)[6], mandating cool roofs for:

- All new government, institutional, and large commercial buildings.

- Residential plots above 600 square yards, while recommending it for smaller ones.

- Occupancy certificates in cities like Hyderabad are now linked to cool roof compliance, a strong enforcement lever.

Cost rationalisation and scale: Telangana’s Schedule of Rates pegs cool roof treatment (paint/tiles) at ₹300/m² (₹28/ft²), <1% of the typical construction cost, making it feasible for public procurement and large-scale rollouts.

Implementation is ecosystem-driven:

- Awareness campaigns co-led with RWAs and NGOs.

- Certified contractor programs to ensure quality.

- A trained applicator network is now active in major cities nationwide.

- Impact at scale: By 2023, Telangana had covered 7.5 km² of roofs, with ~40% of uptake driven by community participation and PPP models showcasing an inclusive model for replication.

Other states are following suit:

- Ahmedabad has embedded cool roofs into its Heat Action Plan, applying them in informal settlements with donor support.

- Andhra Pradesh is scaling pilots under its housing program across 2.8 million homes.

- Delhi, Maharashtra, and Uttar Pradesh are developing or embedding cool roof measures into urban cooling or housing policies.

- Despite momentum, total cool roof coverage in India remains under 1% of eligible urban roof stock, underlining the need for bolder scale-up strategies.

However, at a national level, the total cool roof adoption still covers less than 1% of the eligible urban roof stock.[4]Cool roof adoption in India is being driven through three distinct implementation levers -policies, public programs, and community-led initiatives, each with varying impact, enablers, and constraints. The table below outlines a comparative analysis to guide strategic scale-up

| Lever Type | Examples | Scale of Impact | Enablers | Limitations | Ideal Use Case |

| Standalone Cool Roof Policy | Telangana Cool Roof Policy (2023–2028) | High | Political will, budget allocation, mandate through bylaws, integration with building approvals | Slower initial uptake due to administrative processes; success hinges on enforcement | Institutionalising cool roofs in new construction and retrofits at scale |

| Government-led Program with Community Participation | Ahmedabad HAP, Telangana PPP/co-funded implementations | Medium to High | Public-private partnerships, funding support, integration with housing missions (PMAY-U) | Requires ongoing coordination between multiple actors; sustainability post-project can be weak | Scaling retrofits across low-income housing clusters under existing public programs |

| Community/CSO-led Initiatives | Donor-supported pilots in informal settlements (e.g., NRDC/ASCI in Hyderabad, Ahmedabad) | Low to Medium | Donor support, NGO capacity, grassroots awareness, alignment with heat resilience goals | Hard to scale without formal policy backing; may lack technical standardization | Piloting, demonstrating proof of concept, and reaching last-mile communities quickly |

Table 3: Implementation levers for Cool Roofs adoption

Market Landscape in consultation with the industry:

- Market Size & Growth: India’s cool roof coatings market is relatively small but growing. IMARC estimates it at ~US$132 million in 2024, rising to ~US$220 million by 2033 (≈5.8% CAGR)[7]

- Product Segments: Elastomeric acrylic coatings dominate (~67% globally), with premium ceramic/IR-reflective variants emerging.[8] Cool roof tiles are available but remain niche due to higher cost; no public figures exist for cool-tile share specifically, but India’s roofing tiles market (all types) was ~$6.5 billion in 2021.[9]

- Adoption Trends: Telangana's 2023 policy targets 300 km² of cool roofs by 2028. Delhi’s 2025 HAP includes pilot installations. Ahmedabad has implemented cool roofs in informal housing through public-NGO partnerships.

- Deployment Scale: Vendor consultations indicate increasing adoption in metros like Mumbai, Hyderabad, Bangalore, and Chennai. Some vendors report installations exceeding 10 million sq. ft.

While the policy framework for cool roofs is steadily strengthening, broader adoption now depends on expanding the market ecosystem and deepening community engagement. This includes increasing the availability of quality materials, building a skilled workforce, and encouraging uptake by private developers and housing societies. Emerging success stories such as Telangana’s public outreach campaigns and Ahmedabad’s slum rehabilitation programs demonstrate how cool roofs can transition from scattered pilots to a mainstream strategy for urban climate resilience.

Challenges for Cool Roofs Adoption in India

While the benefits of cool roofs are well-proven, scaling up this solution across India faces several challenges, as discussed with various cool vendors, Lodha and other partners working in cool roofs.

Policy Challenges

- Lack of national standards defining material properties or application protocols, creating ambiguity for implementers.

- Limited integration of cool roofs into building codes, urban development policies, and the Schedule of Rates (SOR), which restricts adoption in public projects.

- Incentives like subsidies, tax rebates, or mandates are sparse. Programs like PMAY-U promote climate-sensitive design, but cool roofs often remain low-priority.

- Even in states with mandates (e.g., Telangana), implementation depends heavily on robust monitoring and contractor capacity. For instance, while Telangana mandates cool roofs in government buildings, scaling this across public housing will require contractor training and diligent oversight.

Technology Challenges

- Lack of uniform technical standards in India defines what qualifies as a “cool roof” (e.g., minimum solar reflectance, thermal emissivity, material durability).

- Absence of performance benchmarks tailored to India’s diverse climatic zones.

- Lack of performance monitoring frameworks, few systems track real-world impacts like surface temperature reduction, energy savings, or occupant comfort.

- Limited data on product lifespan, aged SRI, and cooling impact under varying rooftop conditions (e.g. shaded vs. unshaded, flat vs. sloped).

Market Challenges

- Upfront costs, while modest per unit, become substantial when scaled city-wide, e.g., treating all viable roofs in Chennai was estimated to cost ₹918 crore (~USD 111 million).

- In low-income housing, even minimal cost can be a deterrent without subsidies or external financing.

- In rental or multi-owner buildings, split incentives reduce motivation to invest; the payer isn’t always the beneficiary.

- Cool roofs often compete with other household priorities (e.g., kitchen upgrades) and may be seen as non-essential.

- Aesthetic concerns and lack of clarity (e.g., fear of white coatings getting dirty) also hinder uptake.

- Retrofitting is seen as inconvenient, e.g., requiring temporary removal of water tanks, terrace access disruptions, or surface preparation unless the benefits are strongly demonstrated.

Operations & Maintenance Challenges

- Coatings typically require reapplication every 5–7 years, yet most housing authorities lack maintenance planning frameworks.

- Public housing programs traditionally do not budget or contract for long-term maintenance of cool roof surfaces.

- Without structured models (e.g., AMCs or vendor support), sustaining cooling performance post-installation is a challenge.

- There’s often no clarity on who is responsible for long-term upkeep: the builder, the facility manager, or the residents.

- In low- and mid-rise housing, rooftops often serve as active spaces for daily use. The glare from highly reflective cool roofs can make them uncomfortable.

Awareness Challenges

- Many homeowners, resident welfare associations (RWAs), and even developers are unaware of cool roof performance benefits.

- Perceptions about aesthetics, maintenance hassles, or lack of durability create hesitation.

- The Chennai pilot confirmed that seeing local, relatable examples significantly boosts willingness to adopt.

- Demonstration-led awareness and peer learning remain essential for mass uptake.

Skilled Personnel & Ecosystem Gaps

- The supply chain for cool roof products and installation services in India remains fragmented.

- There is a shortage of trained applicators who understand surface preparation, coating thickness, curing time, and maintenance needs.

- Improper application, such as uneven coatings or poorly prepped surfaces, can undermine performance.

- Telangana’s policy addresses this through certified vendor programs and training drives, but similar capacity-building is missing in most states.

- A scalable ecosystem of certified vendors, contractors, and maintenance agencies is critical for quality and reliability.

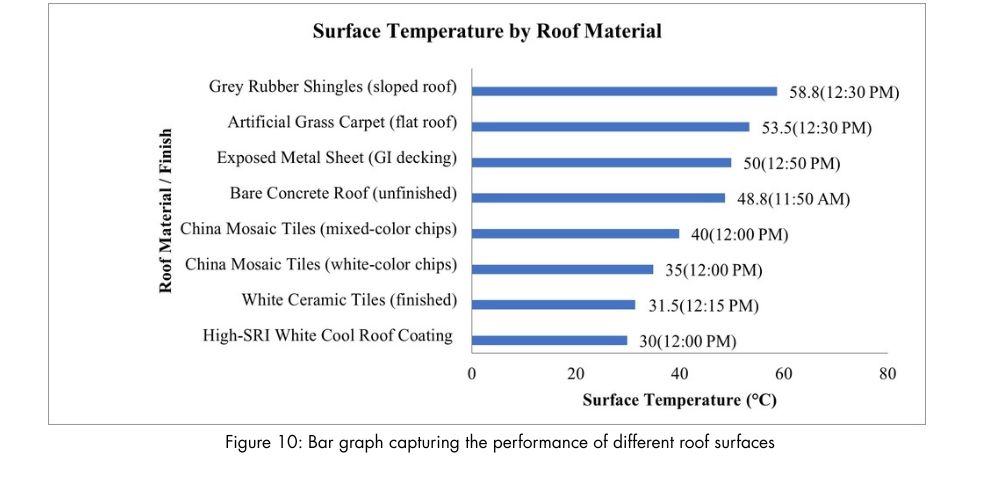

To better understand roof surfaces and how these challenges manifest on the ground, a site survey was conducted to evaluate the real-world performance of different roof materials. This study establishes the thermal performance of commonly used roofing surfaces.

Empirical Roof Temperature Measurements: Insights from On-Site Monitoring

he site survey (conducted in January and March 2025) was conducted to measure the roof surface temperatures at different time intervals using an infrared thermal imager.

Site Context

An integrated township by Lodha in the Mumbai Metropolitan Region, designed around climate-responsive planning. The built typology includes high-rise clusters (17–23 floors, 50–70 m) with flat RCC rooftops predominantly finished in China mosaic tiles, often with significant rooftop service coverage (~85% shaded). Villas under construction feature unfinished cement, concrete or cool tiles on the roof surface. Building designs incorporate recessed balconies, vertical ventilation gaps, and green buffers to reduce heat gain. These interventions have enabled Palava to maintain ambient temperatures up to 3°C cooler than nearby Kalyan-Dombivli and 2°C cooler than Mumbai, establishing it as a model for sustainable urban development.

Documenting the thermal performance of various roofing materials along with observations on shading, material properties, and microclimatic influences, as summarised below.

Building Typologies

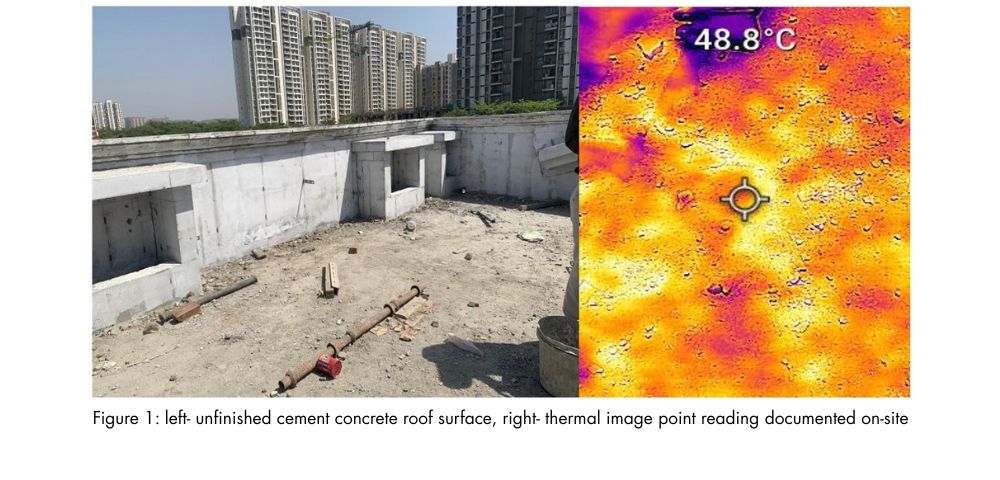

- Under construction, Villa- Roof Surface- Unfinished cement concrete.

Site observations - Flat Unfinished Concrete surface, (@11:50 am): 48.8°C

Inference - Extremely hot surface – unfinished concrete absorbs maximum heat, reaching ~49°C. Without any reflective or insulating finish, it leads to extremely high roof temperatures and should be avoided as a final layer.

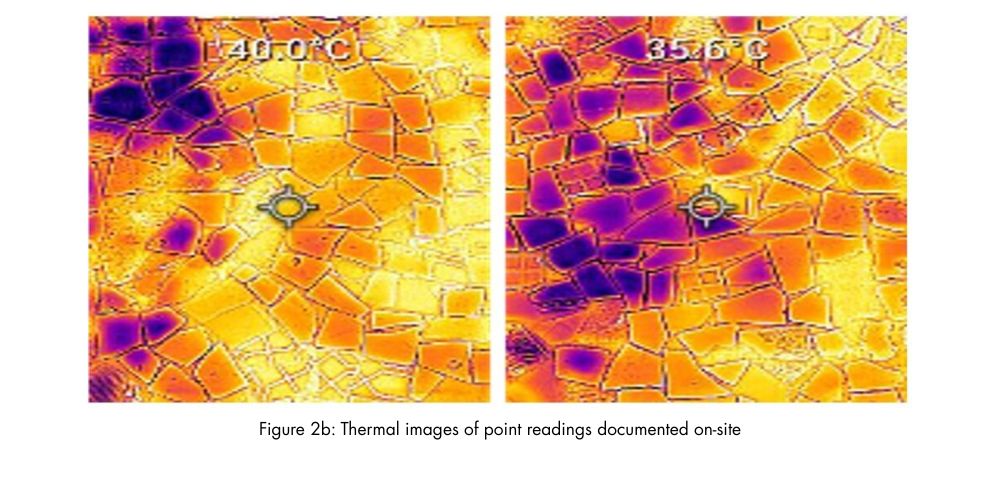

2. Fully constructed High-rises -Roof Surface- Mixed coloured China mosaic tiles (Azzurra, Urbano, Trinity) (UNSHADED)

Site Observations - China mosaic tiles surface (@12:00 pm): Mixed colored- 40℃, White- 35°C (white)

Inference - Moderately cooler than bare concrete. The mosaic’s light-coloured portions help, but the mixed dark chips make it ~8.5°C hotter than an all-white tile roof under a similar sun. Provides some cooling benefits, but is less effective than uniform white surfaces at reflecting solar radiation.

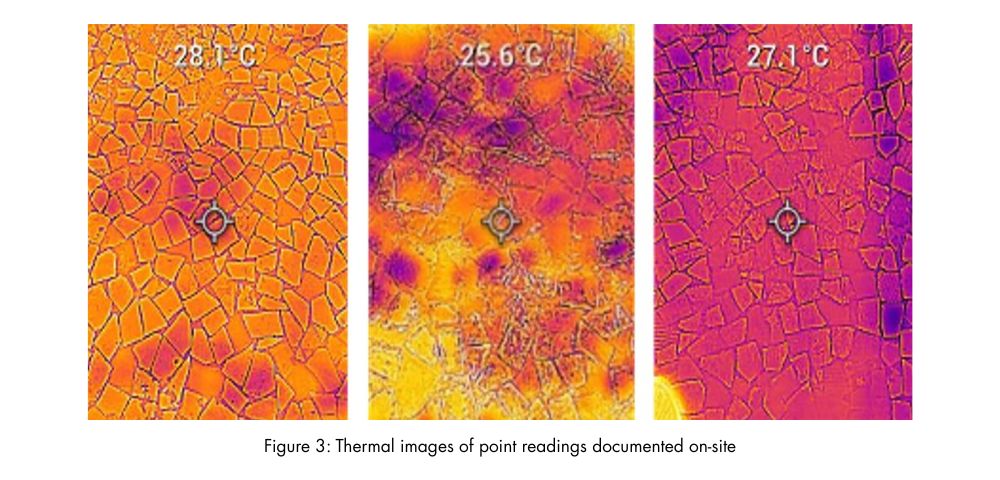

3. Fully constructed High-rises -Roof Surface- Mixed coloured China mosaic tiles (Azzurra, Urbano, Trinity) (SHADED)

Site Observations - China mosaic tiles surface SHADED (@12:00 pm): 25.6℃ to 28℃

Inference - The shaded portions of China's mosaic tile roofs recorded surface temperatures between 25.6°C to 28°C, which is significantly cooler than their exposed counterparts. This demonstrates that combining even moderately reflective materials with passive shading (from services or structures) can reduce roof surface temperatures by an additional 6–10°C.

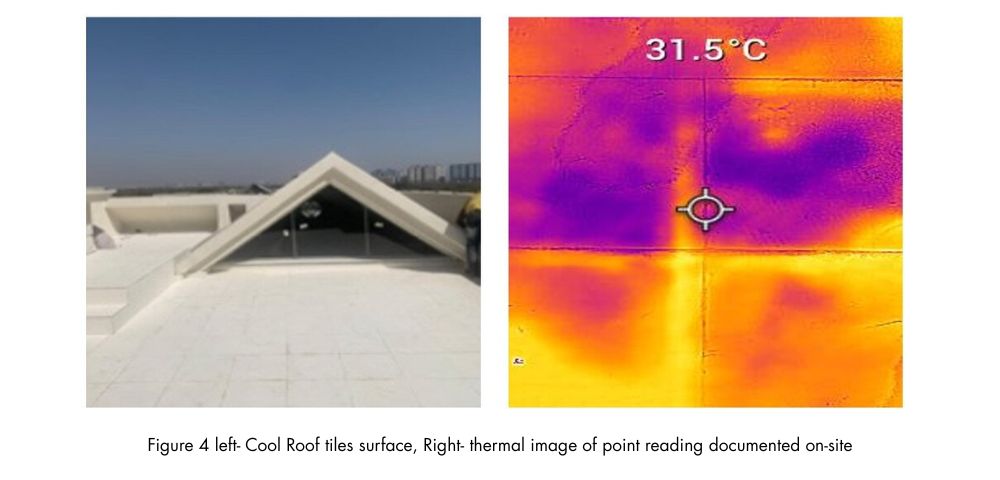

4. Under construction Villa- Roof surface-layered with white tile.

Site observations – White tile surface (12:15 pm): 31.5 ℃ (SRI value- 99)

Inference- The coolest surface was observed. High-reflectivity white tile kept the roof ~8–17°C cooler than other materials in similar conditions. Confirms that predominantly white, reflective finishes are the most effective passive cooling solution.

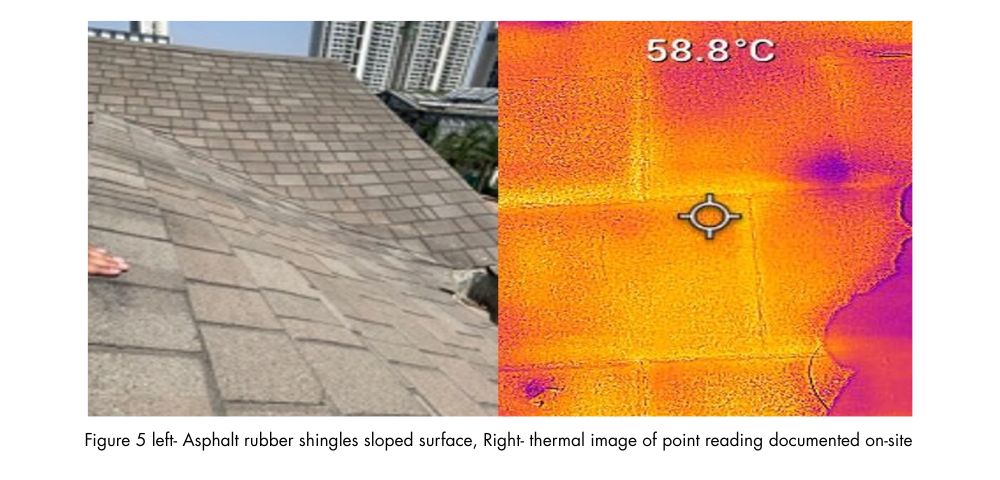

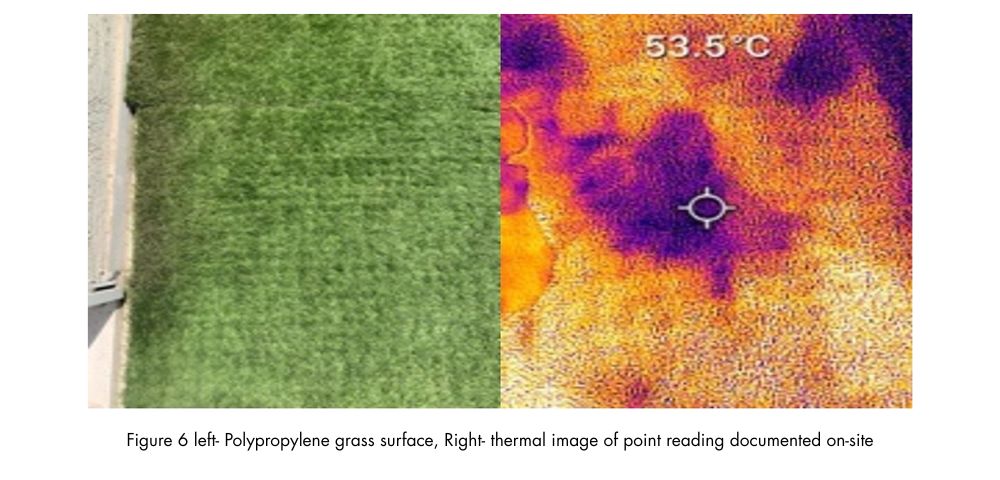

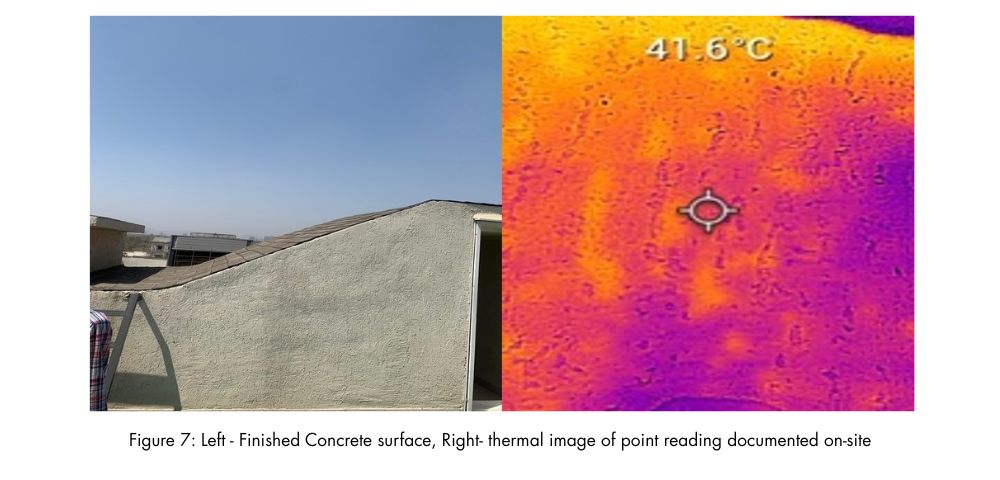

5. Fully constructed prototype Villa-Roof flat surface temporarily finished with grass carpet made of polypropylene and sloped surface finished with grey rubber shingles.

Site Observations - Rubber shingles surface (@12:30 pm): 58.8°C

Site Observations - Artificial grass surfaces (@12:30 pm): 53.5°C

Site Observations - Finished concrete surface (@12:30pm): 41.5°C

Inference - Severe heat buildup. Dark rubber shingles reached nearly 59°C – about 17°C hotter than a normal finished concrete surface nearby. Despite modern aesthetics, these shingles greatly increase roof heat gain and have proved highly ineffective for thermal comfort.

High heat retention. The green synthetic turf, while visually ‘cool’, reached >53°C, about 12°C hotter than the reference concrete surface. Acts akin to a dark surface and significantly increases roof temperature, unsuitable for warm climates.

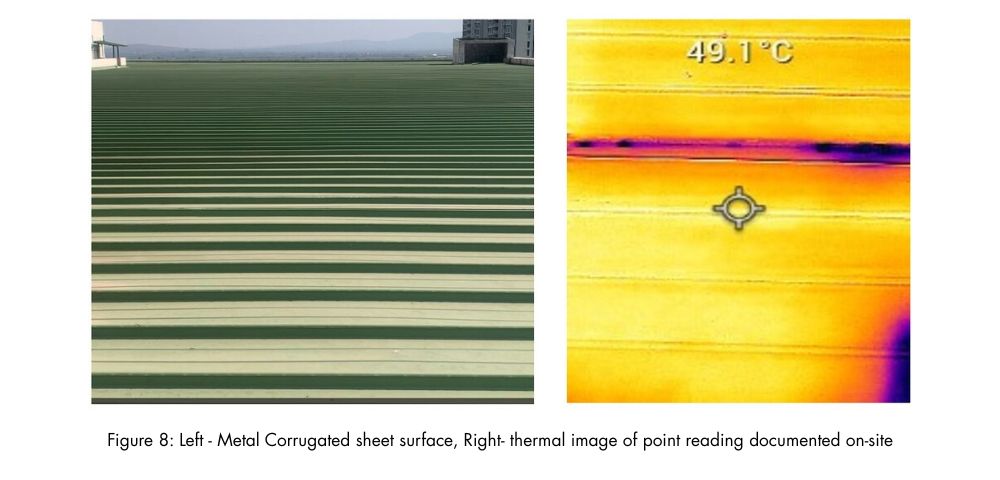

6. MLCP-Multi Level Car Parking Roof surface- Metal Corrugated Sheet

Site Observations - Corrugated Metal Sheet surface (@12:50 pm): 50°C

Inference- Very hot surface – uncoated metal deck hit 50°C. Metal surfaces heat quickly, and without any cool coating or insulation, this roof was ~18.5°C hotter than the white tile roof at the same time. It can exacerbate local heating and discomfort.

"Source: Palava Phase-2 site survey by RMI, Jan–Mar 2025. Temperature readings were taken with an infrared thermal imager on clear sunny days (ambient ~35–37 °C)"

To provide a comparative reference, field observations from a similar mid-rise low-income housing project in Chennai are included below. Conducted under comparable warm and humid climate conditions, and at similar midday ambient temperatures(35-38°C) and time intervals, the measurements demonstrate the thermal performance of high-reflectance cool roof coatings in a parallel urban context.

Building Typology- Low-income Housing Roof in Chennai

Site Observations - High-SRI White Acrylic Cool Roof Coating (SRI 102) (@12:30 pm): 36°C

Inference- High-performance cool roof coating maintains surface temperatures significantly lower, even under similar climatic conditions. Coating certified to SRI 102, SR 0.81, and Emissivity 0.90, offering strong passive cooling performance for mid-rise affordable housing clusters.

To summarise the observed surface temperature data in a more intuitive format, the following graph illustrates the relative thermal performance of different roof materials recorded during the site survey.

Discussion of Findings from the Site Data

- Impact of White Tiles:

The on-site observations at Palava provide vivid evidence of how different roofing materials and conditions influence thermal performance. A clear hierarchy emerges where bright white, reflective surfaces stay coolest, while dark, unreflective materials become extremely hot. The white tiled roof stayed around 31–32 °C, and the white China mosaic stayed around 34-35 °C in the middle of the day, which was over 20 °C cooler than the worst-performing surface (dark shingles at ~59 °C). This huge differential underscores the impact roof albedo has on surface heat. Even compared to a conventional finish, the white tile was 10+°C cooler than plain concrete, confirming that high-reflectance treatments can dramatically reduce surface temperatures in real conditions.

- Impact of mixed colour chips in China mosaic:

A notable finding was the relatively good performance of the traditional China mosaic finish (which combined light and dark chips). Its 40 °C surface temperature indicates some cooling benefit versus bare concrete, thanks to the reflective chips. However, the data also revealed a gap: the inclusion of darker-coloured pieces raised their temperature by ~8–9 °C compared to an all-white surface, which was up to 5°C cooler. This suggests that common construction practices could be optimised – e.g. using predominantly white ceramic chips in the mosaic instead of mixed colours – to enhance reflectivity without significantly altering the technique or cost. For developers and contractors, such a tweak in material choice can mean the difference between a moderately cool roof and an excellent one. China chips are a durable and cost-effective solution for terrace surfaces, as their small joints help dissipate shrinkage and thermal stresses, reducing cracking and ensuring robust waterproofing, while also offering effective surface reflectivity.

- Impact of Grey Shingles and Grass:

Perhaps the most surprising (and cautionary) results were for materials that one might not intuitively suspect to cause extreme heating: the grey rubberised shingles and the artificial grass carpet. Both are modern roofing options sometimes used for aesthetics or insulation, yet the survey showed they perform very poorly under the sun. The dark bituminous rubber shingles absorbed enormous heat (nearly 59 °C surface), far worse than even unfinished concrete. The artificial turf – often presumed to have a cooling effect because it’s “green” – in reality, traps heat and reaches over 50 °C. In fact, both these materials ended up much hotter than a plain concrete roof would be. This was a striking finding: it reveals a performance gap where these materials can inadvertently exacerbate thermal problems. It highlights the need for awareness among architects and designers– a material’s appearance or intuition can be misleading; empirical thermal performance data is critical. Both the shingles and turf would be unsuitable in hot climates without some corrective measures (replacing them with high-SRI alternatives like ceramic shingles or lighter shade materials).

- Impact of Shading and installation of building services on the roof:

On the high-rise roofs, although the material (mosaic tiles) was only moderately reflective, the fact that ~85% of the roof area was covered by utilities (solar water heaters, HVAC equipment, etc.) meant that much of the surface was shaded for large parts of the day. Field readings showed shaded sections stayed 6–10 °C cooler than adjacent exposed sections. This indicates that introducing shade (via mechanical equipment, solar PV panels, pergolas, or even high albedo paint under structures) can significantly cut down surface temperatures. In design terms, this suggests a combined approach: roofs that will hold solar panels or other installations can benefit from both the shade they provide and a cool roof treatment on exposed portions for maximum effect. A study showed that applying cool roof coatings led to a 5–10% improvement in solar panel efficiency by reducing rooftop surface temperatures under Middle Eastern climatic conditions.[10]

- Trade-off between the top two performing surfaces:

While white tiles demonstrated the best thermal performance in the Palava study, maintaining surface temperatures around 31–32 °C, choosing between cool tiles and coatings is not just about performance. Tiles, though highly durable and maintenance-free, are labour-intensive, expensive, and add structural load to the roof. This makes them ideal for new construction but challenging to retrofit, especially in existing buildings with service-equipped terraces or older roof slabs. Coatings, on the other hand, offer comparable surface temperature reductions (9–12 °C vs concrete), are lightweight, and are easier to apply even on complex or cluttered rooftops. However, they require periodic maintenance and reapplication every 5–7 years. The choice between them often depends on the project context: structural feasibility, cost constraints, ease of application, and lifecycle goals.

Recommendations and Call to Action

This trade-off analysis reinforces the need for targeted application strategies and customised technical guidelines based on building typology, usage patterns, and resident behaviour. Table 4 below summarises feasible cool roof solutions based on roof typology. However, their suitability and long-term effectiveness are highly dependent on site-specific factors such as structural conditions, usage patterns, climatic zone, roof accessibility, and maintenance capacity. A detailed assessment should be conducted before selecting the most appropriate solution.

| Roof Type | Recommended Cool Roof Approach |

| RCC Roof (New or Old) | White elastomeric/acrylic-based reflective coatings, cool tiles, and white China mosaic tiles (porcelain/ceramic)- cost-effective; tiles require proper installation. Coatings have 3–5-year reapplication cycles. |

| Sloped Roofs | High-albedo options like reflective clay tiles or ceramic-coated metal shingles are preferred. |

| Metal Roofs | TPO (Thermoplastic Polyolefin) /PVC (Polyvinyl Chloride) membranes or reflective paints (e.g., fluoropolymer-based), Factory-coated white metal panels, PVDF (Polyvinylidene Fluoride), these membranes have high SRI and good durability. |

| Temporary Roofs | Limewash or white reflective paints/ TPO/PVC membranes |

Table 4 : Recommendation for a Cool Roof solution for different typologies

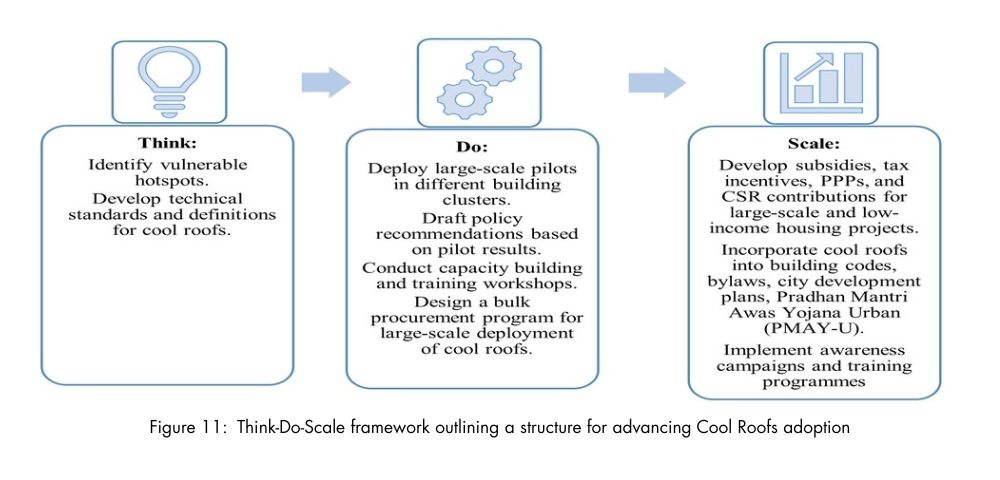

Despite their potential, adoption remains limited due to a lack of clear guidelines, financial incentives, and institutional mechanisms. The Think-Do-Scale framework below outlines a structured approach for advancing Cool Roofs adoption.

- Think – Short-Term (0-2 Years): Establish foundational planning, enhance inter-departmental coordination, and secure financing to lay the groundwork for implementation.

- Do – Medium-Term (2-4 Years): Conduct large-scale pilots, refine policies based on pilot insights, train the workforce, and initiate early-phase implementation.

- Scale – Long-Term (4+ Years): Institutionalize Cool Roofs within urban planning, expand financing beyond government support, and transition towards a self-sustaining, market-driven initiative.

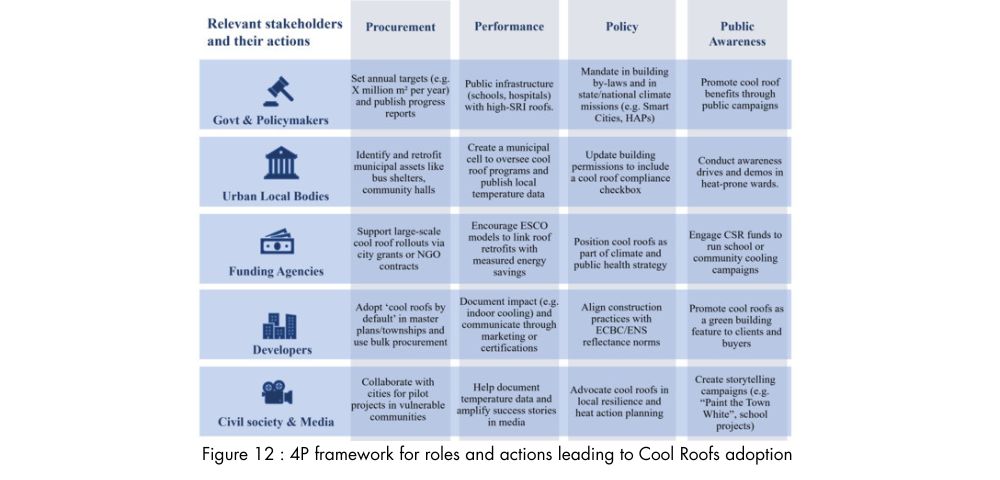

The 4P framework, Procurement, Performance Monitoring, Policy, and Public Awareness, shown below, demonstrates that cool roof adoption is not the responsibility of a single actor but a multi-stakeholder mission. Each group, government, ULBs, developers, funders, and civil society, plays a distinct yet interconnected role. Success hinges on aligning these actions: robust policy mandates must be backed by procurement in public projects, performance tracking, and community engagement. Where one lever is missing, adoption slows. But when all four Ps are activated together, cool roofs become a scalable, replicable strategy for climate resilience, especially in heat-vulnerable cities.

References:

[1] “(PDF) Urban heat island effect in India: a review of current status, impact and mitigation strategies,” ResearchGate. Accessed: Apr. 29, 2025. [Online]. Available: https://www.researchgate.net/publication/386452837_Urban_heat_island_effect_in_India_a_review_of_current_status_impact_and_mitigation_strategies

[2] “Decoding the Urban Heat Stress among Indian cities.” Accessed: Apr. 29, 2025. [Online].

Available: https://www.cseindia.org/decoding-the-urban-heat-stress-among-indian-cities-12191

[3] UCL, “Cool roofs are best at beating cities’ heat,” UCL News. Accessed: Apr. 29, 2025. [Online].

Available: https://www.ucl.ac.uk/news/2024/jul/cool-roofs-are-best-beating-cities-heat

[4] NRDC, “ADDRESSING RISING DEMAND FOR COOLING IN INDIA WITH COOL ROOFS.” NRDC, Nov. 2022. Accessed: Apr. 29, 2025. [Online].

Available: https://ghhin.org/wp-content/uploads/addressing-rising-demand-india-cool-roofs-fs-202210.pdf

[5] “(PDF) Cool Roof initiatives in India: An evaluation of the existing conditions and lessons to be learnt from global best practices,” ResearchGate, Accessed: Apr. 29, 2025. [Online].

Available: https://www.researchgate.net/publication/343261749_Cool_Roof_initiatives_in_India_An_evaluation_of_the_existing_conditions_and_lessons_to_be_learnt_from_global_best_practices

[6] “Telangana’s cool roof policy: pilot demonstration to policy implementation,” Climate Group. Accessed: Feb. 21, 2025. [Online].

Available:https://www.theclimategroup.org/our-work/publications/telanganas-cool-roof-policy-pilot-demonstration-policy-implementation

[7] “India Roof Coatings Market Size, Share, Trends, 2033.” Accessed: May 17, 2025. [Online].

Available: https://www.imarcgroup.com/india-roof-coatings-market

[8] “Cool Roof Coatings Market Size, Share, Growth Report, 2030.” Accessed: May 17, 2025. [Online].

Available: https://www.grandviewresearch.com/industry-analysis/cool-roof-coating-market

[9] “India Roofing Materials Market Size & Outlook, 2030.” Accessed: May 17, 2025. [Online].

Available: https://www.grandviewresearch.com/horizon/outlook/roofing-materials-market/india

[10] H. Altan, Z. Alshikh, V. Belpoliti, Y. K. Kim, Z. Said, and M. Al-chaderchi, “An experimental study of the impact of cool roof on solar PV electricity generations on building rooftops in Sharjah, UAE,” Int. J. Low-Carbon Technol., vol. 14, no. 2, pp. 267–276, Jun. 2019, doi: 10.1093/ijlct/ctz008.

You may also like

Enquire

Enquire

Call

Call

chat

chat

Search

Search